[tx_slider style="default" category="mpg-series-rectangular-gyratory-screener" delay="8000" parallax="yes" items="2" transition="fade" title="hide" desc="show" link="hide" align="left" height="660" textbg="shadow"]

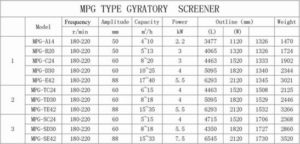

MPG Rectangular Gyratory Screener

The MPG rectangular gyratory screener has the similar features with our M series rectangualr gyratory screener on working principle, screening efficiency and application range. But the screen deck structure is different with it.

The MPG rectangular gyratory screener has an unique and economic design which not only reduce the downtime but also increase the productivity.

Gyratory-reciprocating motion provides efficient distribution, stratification, and separation resulting in higher yields and less rejection of good material. It no longer needs to remove the top cover of machine to access screens and ball trays. Just needs single operator to manage whatever on maintenance and inspection of the screen.

All screens of the MPG rectangular gyratory screener can be inspected in less than 10 minutes and mesh screen can be changed in 2 minutes, 80% faster than common M Series rectangular gyratory screener.

CONTACT US FOR MORE INFORMATION

Working Principle

The Gyratory Reciprocating Motion gradually diminishes along the length of the machine to an elliptical path and finally to a nearly straight line motion at the discharge end.

The Gyratory Reciprocating Motion gradually diminishes along the length of the machine to an elliptical path and finally to a nearly straight line motion at the discharge end.

1. Circular motion at feed end

Material diffusion across the full width of the screen surface

Invasively puts material forward

2. Become elliptical motion at centreLong stroke elliptical action

Enhances product stratification

Conveys material at high capacity

Removes near-size particles

Improves screening efficiency

No vertical component ensures material is in constant contact with the screen surface.

Products Advantages

1.Adopt Special Gyratory Motion

Gyratory-reciprocating motion provides efficient distribution, stratification, and separation resulting in higher yields and less rejection of good material.

2.Individual Screen Panel

Individual screen panel, each screen layer can be installed 2-8 pcs panels as different model.

Not only easy to operate but also save the space.

3. Easy Operation

Stable operation, high performance, reduce the screening costs

Only need single operator to inspect and maintain

4. Easy Access Screens

Screens and ball trays are accessible from the side of machine.

No longer need to remove the top cover of machine to access screens and ball trays.

5. Wearable and Reliable

High quality and wearable structure featuring abrasion and corrosion resistant stainless steel.

6. Bouncing Balls

Bouncing balls keep screen openings clear, improving efficiency and capacity.

7. Quick Lock Clamps

Quick lock clamps ensure uniform sealing of cover and screen decks

8. Tension clips

Tension clips keep rapid screen changes and less downtime

Applaction

The MPG gyratory screeners is widely used in chemical industry, agriculture industry, food, medicine, mineral, plastic and recycling industry etc. The high screening efficiency and stable function have been proven by hundreds of practical applications, plus easy operation and maintenance advantages, therefore, the application scope of MPG gyratory screeners supplied by Megayoung will be larger, and could meet much more special requests on material screening.

The MPG gyratory screeners is widely used in chemical industry, agriculture industry, food, medicine, mineral, plastic and recycling industry etc. The high screening efficiency and stable function have been proven by hundreds of practical applications, plus easy operation and maintenance advantages, therefore, the application scope of MPG gyratory screeners supplied by Megayoung will be larger, and could meet much more special requests on material screening.

Brochure download

The PDF brochure attachments contain a detailed product instruction and operation methods.